How to Measure a Box Dimensions ( A Detailed Guide ) 2025

Want to ensure a cost-effective and efficient shipping process? Well, then, you need to learn how to measure box dimensions accurately. Accurate measurements of your box make all the difference. It allows you to streamline shipping logistics, ensure customer satisfaction, and prevent wastage of materials (resources).

In this comprehensive box measurement guide, we will look into every crucial step of “how to measure a box dimensions accurately”.

This guide will help you master the art of perfect packaging so you can minimize shipping costs, improve customer experience, ensure safer deliveries, and optimize the shipping process.

So, let’s dive in. We will begin by understanding what box dimensions are and why they are important.

Understanding Box Dimensions

The key to crafting perfect packaging boxes always begins with understanding box dimensions and knowing how to measure them perfectly.

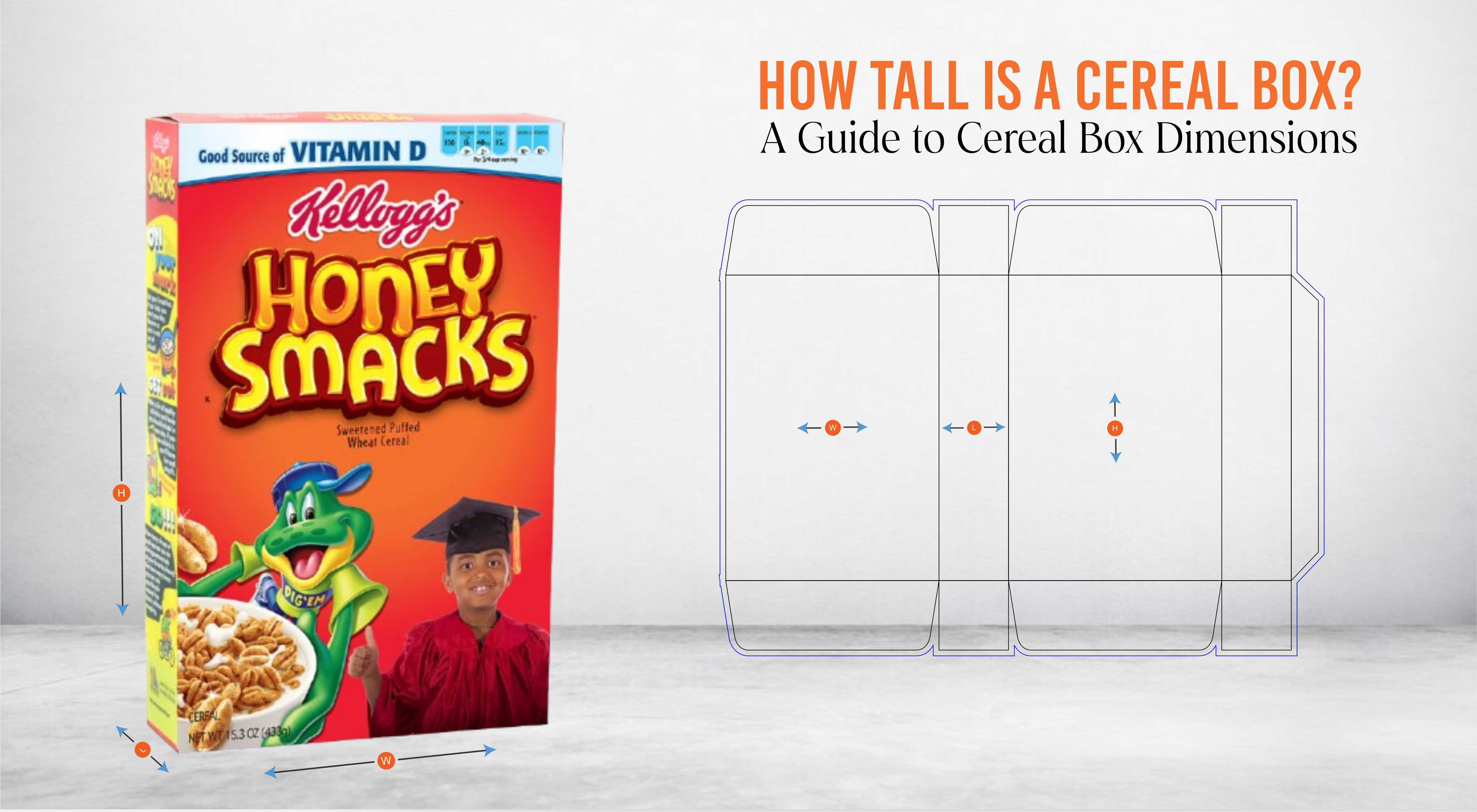

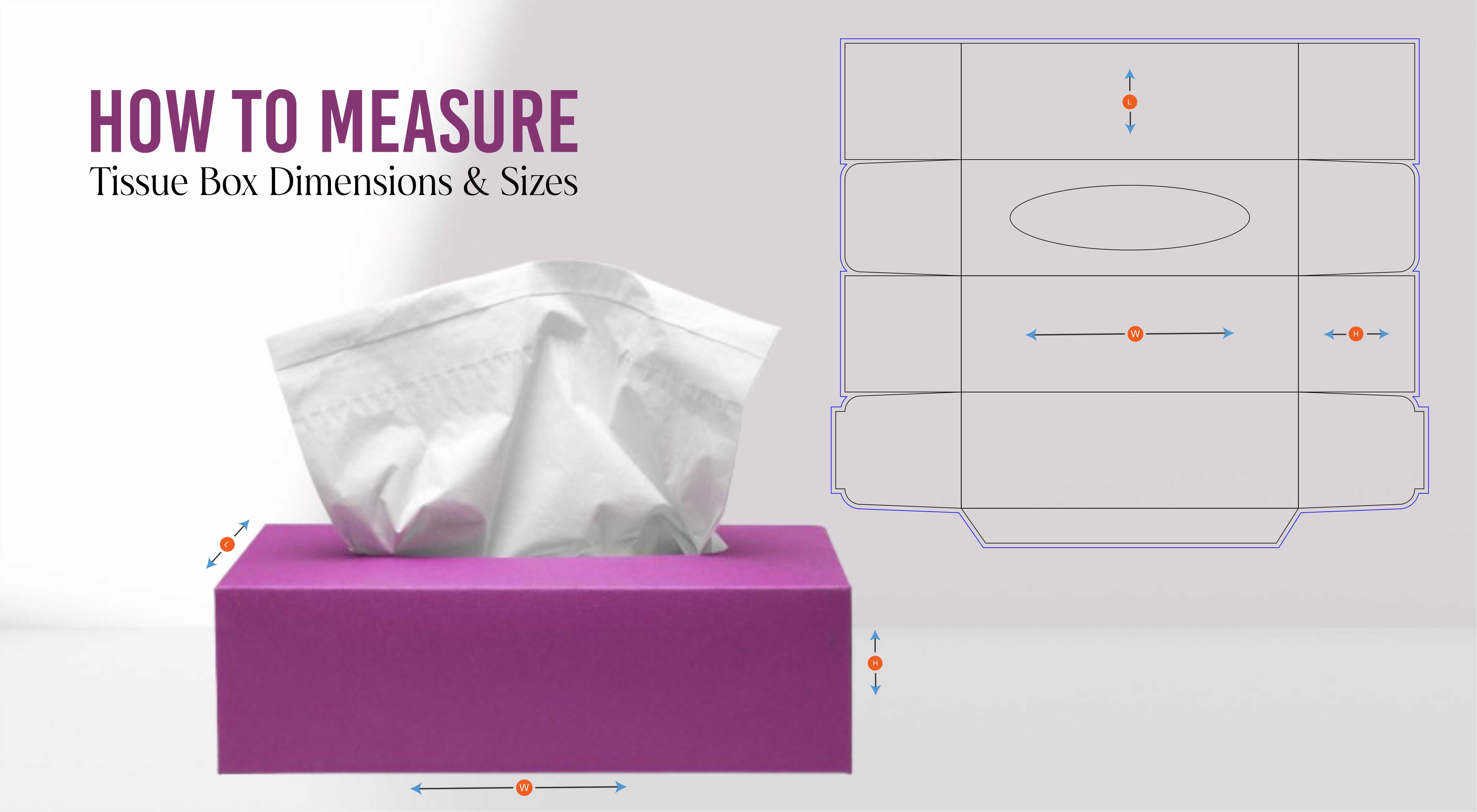

The three crucial measurements you need are - length width height (also known as depth). You can find out your box size easily by using these dimensions.

The industry standard for recording the box dimensions is as follows:

Length x Width X Height (l x w x h)

OR

Length x Width X Depth (l x w x d)

Imagine your box with length (the longest side horizontally), width (the shorter side horizontally), and height/depth (the vertical side). If your product is tall or facing upward, the height/depth will be the most prominent dimension in this case. The length and width will be smaller than the height/depth

In case your product is smaller and wider, the length will be more prominent than the width and height/depth.

Using a tool, you can measure these box dimensions and round each one to the nearest whole inch for best results. Your product will help you decide whether to use height or depth for the box as a unit of measurement.

Why Are Accurate Box Measurements So Important?

Regardless of box size or orientation, it’s crucial for every brand to figure out the exact measurements of the box. Why? Because when it comes to packaging, accurate measurements lay the foundation for several other benefits.

For instance, you can prevent material waste and showcase your commitment to sustainability.

You can also reduce the cost of production, ensure better product protection, and enhance customers’ overall experience.

Now that we know how beneficial accurate box dimensions are, let’s look into the tools that help ensure accuracy.

Essential Tools for Measuring box dimensions

There are several measuring tools for boxes that you can use to figure out the dimension measurement of any box. However, the ruler, tape measure, digital caliper, and laser distance measurer are some of the best tools for measuring dimensions.

Let’s take a closer look into each of these and figure out how they can help you out.

The Ruler

Rulers are timeless. They are easy to use and readily available. Rulers come in handy when you have to take measurements of smaller boxes. Thanks to its rigid nature, it is one of the most accurate tools you can use.

Tape Measure

In contrast to the ruler, the tape measure is flexible and easy to bend or stretch. This works perfectly for larger boxes and for navigating boxes with corners.

A study published in the International Journal of Packaging Science states that tape measures reduce the time taken to measure a large box by up to 30%.

However, since it is flexible, you need to be more careful and steady to ensure accuracy.

Digital Calipers

If you are looking for ultimate precision and modernity, digital calipers are perfect for you. Not only are they extremely accurate, but they also read aloud the measurement and leave no room for error.

The only drawback is that they are mostly suitable for smaller boxes and come with a steeper price tag.

Digital Laser Distance Measurer

Finally, we have the laser distance measurer. It is a tool that is all about accuracy. Not only is it digital and quick, but it also gives hassle-free and accurate measurements box dimensions with a laser point. It is best for measuring larger boxes.

However, it also comes with a hefty price tag and is battery-operated.

Step-by-Step Guide How to Measuring Box Dimensions

Now that we have learn about the tools and dimensions, let’s dive deeper and look at how to measure box dimensions.

Though measuring a box may seem like a piece of cake, it takes patience and accuracy to get it right. Here is a step-by-step box measurement guide to help you out.

Prepare Your Workstation

Having a clean, uncluttered, and leveled surface is key to getting accurate measurements. So, go ahead and prepare your workstation and remove distractions that may affect your results.

1. Measure the Length

Now, let’s start with measuring the length of the box. Take your tool of choice and measure from one edge to the other on the longest horizontal side. Note down the reading and round off to the nearest inch.

2. Measure the Width

Do the same for the width. Take your tool and measure the smallest opposite horizontal side from one edge to the other. Note down this number as well and round off to the nearest inch.

3. Measure the Height/Depth

Last but not least, take your tool and measure the height/depth of the box from one vertical edge to the other (from base to the top).

Internal Vs. External Dimensions

Indeed, the length, width, and height/depth are the three key measurements that build the foundation of your packaging. However, there is another concept that can make or break your box. Knowing how to measure internal and external dimensions is imperative.

External dimension means the entire box (outside measurements lxwxh or lxwxd). On the other hand, internal dimensions are the actual space available inside the box.

When it comes to packaging, internal dimensions will help with secure product fitting, but external dimensions take precedence in shipping. (reference images below)

Tips To Ensure Accurate Measurements of Box

Here are a few key tips to ensure you can get accurate readings and avoid any mishaps.

Use The Right Tool

Your box size and budget will help you decide which tool is perfect for you. Rulers or digital calipers are perfect for measuring smaller boxes with rigid corners. In contrast, a tape measure or laser distance measurer is the right choice for measuring larger boxes.

Check The Calibration Of Tools

Before measuring anything, make sure your devices are correctly calibrated. It will help you avoid any mistakes. As we know, when it comes to measurements, even the slightest errors can be costly and wasteful.

Use The Same Measurement Unit For Everything

Another key aspect to be aware of is the unit of measurement. You can pick any unit - inches, centimeter, millimeter, etc.). However, just make sure you measure each dimension in the same unit to ensure consistency.

Take Irregular/Custom Shapes Into Account

A box may be rectangular, square, round, or specially made into any custom shape. So, leave room for irregularity. No matter the shape of the box, start by measuring the widest or tallest points.

Get A Second Opinion

When you decide to begin taking measurements of the box, get a colleague or peer to stand by and verify or double-check the measurements. It is the best way to minimize the risk of errors.

Measure More Than Once

Another way to ensure accurate measurements is by measuring each side more than once. This works best in cases where a second opinion is not an option.

Even though measuring a box looks like a simple process on the surface, it is intricate and requires steady hands. So, organize your space before you begin and follow this guide for the best results.

Calculating Volume for Efficient Packing

There are five basic purposes behind ensuring accurate measurements of the box dimensions.

1. Superior product protection

2. Seamless packaging

3. Reducing material waste

4. Ensuring a cost-efficient delivery

5. Enhancing customer experience

It is crucial that you calculate box volume to make sure all five purposes are fulfilled, and box packing efficiency is ensured. The box volume allows you to determine how well the product will fit in the box. It will also help you get an idea regarding storage and shipment logistics.

To calculate box volume, simply multiply the following three dimensions. Your answer will be in cubic centimeters.

Length x Width x height/Depth = Volume (in cubic centimeters)

Even though it is not necessary to know which measurement corresponds with which dimension exactly, we recommend that you have this information at hand to avoid any mistakes. If you are not a math wizard or just dislike calculations, there are several calculation tools available online that can help make the process easier.

Common Mistakes to Avoid

If you think measuring a box is no big deal, you’d be making a mistake. Ever heard the quote, “The devil is in the details”? In this case, it would be true. Even the most seasoned professionals can slip and make mistakes that are quite costly. So, here are common measuring errors that can help you avoid box measurement mistakes.

Relying On External Measurements Only

If you only rely on the external measurements of the box, you will surely get misfit packaging boxes. But the damage does not stop here. Materials are wasted, product integrity is compromised, customers get dissatisfied, and the investment made in packaging goes down the drain. So, always consider both external and internal measurements, as well as box volume.

Not Rounding Off At The Right Time

It is the second most common error, and usually, the person taking measurements rounds off figures too early. It leads to significant mishaps and costs a whole lot of money in terms of material waste. Since every inch counts, it is best to be precise and round off the figures at the end of all calculations.

Not Considering Material Thickness

The material thickness can significantly impact your measurements by a lot. And it is especially true in cases of corrugated boxes. There is a possibility of up to a 5% deviation in the actual internal space that is available in the box. So, make sure to account for this error and save time, effort, and money.

Only Relying On A Single Measuring Tool

A ruler or tape measure is readily available and may seem like all the tools you need to measure the small and large boxes. However, each tool has its pros and cons. So, relying on one tool is not the answer. It is best to measure more than once using different tools, to be exact.

Not Accounting For The ‘Human Factor’

You can outrun or deny it. Human error is something that can happen to the best of us. That is why it is best to have another person in the room who can double-check the measurements. Or, measuring more than once is another good solution to counter this issue.

In simpler words, accuracy in the measurement of boxes is not just about knowing how to use certain tools or reading the numbers. It is an art that can be mastered by being meticulous and avoiding these common errors.

FAQs about Measuring Box Dimensions

Now, let’s look into some of the most frequently asked questions about measuring box dimensions.

Is the length, width, and height/depth of the box all I need?

As explained earlier in the guide, to ensure accuracy and perfect results, you need to consider more than just the length, width, and height/depth of your box. Depending upon product volume and weight, you need to understand the concept of internal and external measurements. Also, you must account for the full volume of the box (capacity inside the box) for optimal results.

What if my box is shaped irregularly?

Product packaging boxes come in all sorts of shapes and sizes. Each box style has its specific purpose, and whether the shape is standard, irregular, or custom, the principles for measuring the box remain constant. To ensure accuracy, think about the intended use of the box and then measure accordingly. It will help you ensure the most efficient use of space and prevent material waste.

How do I measure my box for shipping?

It is important to consider that shipping service providers often consider the dimensional weight of the box or package, which is based on the volume of the box and not the actual weight. They tend to adjust shipping costs if the dimensional weight of the box exceeds the actual weight. Therefore, calculating the accurate volume of the box is in your best interests.

Conclusion

Measuring accurate box dimensions is a necessity because these numbers dictate the operational costs of doing business. In this detailed and step-by-step box measurement guide, we have covered everything you need. From understanding the basics to the tools you may need to even the most overlooked aspects, everything has been covered for your convenience.

Moreover, this guide demystifies box measurement importance since the success of your business depends on the accuracy of box measurement numbers. These measurements ensure the efficacy of your packaging, provide optimal product protection, bring cost-efficiency, and maximize the role of the box as a brand ambassador.

.jpg)

.jpg)